COMPANY

SMART FACTORY

SMART FACTORY

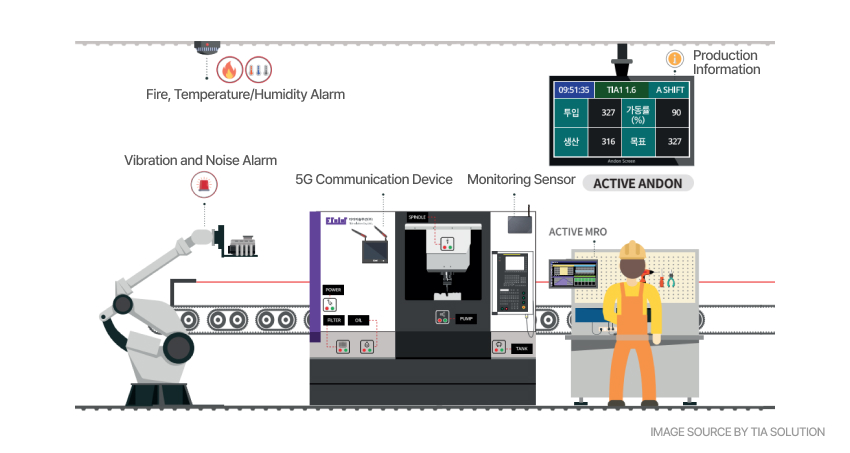

5G Communication-Based Equipment Configuration Diagram

Collection and Analysis of BIT Manufacturing Data: The Core of the Smart Factory System, Applied to Production, Sales, and Inventory Management

- 1) A system has been established to connect 5G communication devices to BIT manufacturing equipment, enabling real-time response to multi-product production. This allows for the transmission of machining data (CAM, G-Code, M-Code) necessary for processing.

- 2) In the event of equipment failure, repairs can take several days, significantly impacting the operations of small and medium-sized businesses. By utilizing sensors installed in manufacturing equipment, predictive maintenance algorithms are employed to prevent failures in advance.

New BIT Manufacturing Method Patent

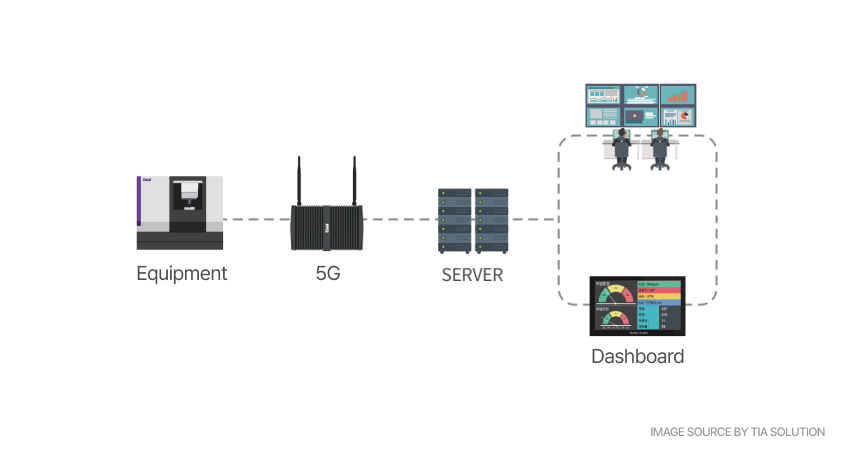

Data Mining via 5G Connectivity to Machining Centers

- 1) To process target materials, machining information converted into G-Code must be input into the equipment. When switching to a new product, the updated G-Code data must be transmitted by connecting a computer to the equipment. By integrating 5G communication devices into the equipment interface, machining codes stored in remote office servers can be transmitted in real time.

- 2) Information generated within the equipment during BIT machining (e.g., rotation RPM, coolant temperature, tool processing time) is collected in real time, analyzed, and utilized as operational data to optimize production.